No products in the cart.

Return To Shop- Home page

- Surgical Sets

Explore Our Surgery Sets

- Surgical Instruments

- Dental Instruments

- About Us

- Our Catalogue

- Blog

- Contact us

Search Products

MENU

Solutions

Surgical Sets

Instruments

High Quality Instrumets

Awareness that health dependent upon habit that we control makes first generation

All Surgical Equipments

Save Upto 30% Flate

Shop Now >

German Steel

Save Upto 30% Flate

Shop Now >

Trusted by Professionals Worldwide

Lasani Surgical Industries is a trusted Surgical Instruments Manufacturer in the medical manufacturing industry, known for delivering precision-crafted surgical instruments to healthcare professionals worldwide. With decades of experience, we have earned our place as a reliable partner to hospitals, clinics, and distributors by consistently providing high-quality, durable, and performance-oriented instruments. As a leading Surgical Instruments Manufacturer, every product we offer is crafted with care, attention to detail, and the needs of the end user in mind.

Our commitment to international quality standards is reflected in our certifications, including ISO 13485:2016 and ISO 9001:2015, awarded by Dynamex Certification Services. We adhere strictly to regulatory requirements and safety protocols, ensuring that every instrument meets or exceeds industry expectations. Additionally, our products comply with the European Medical Device Directive 93/42/EEC, assuring customers of CE conformity and dependable functionality—further strengthening our reputation as a reliable Surgical Instruments Manufacturer in the global healthcare market.

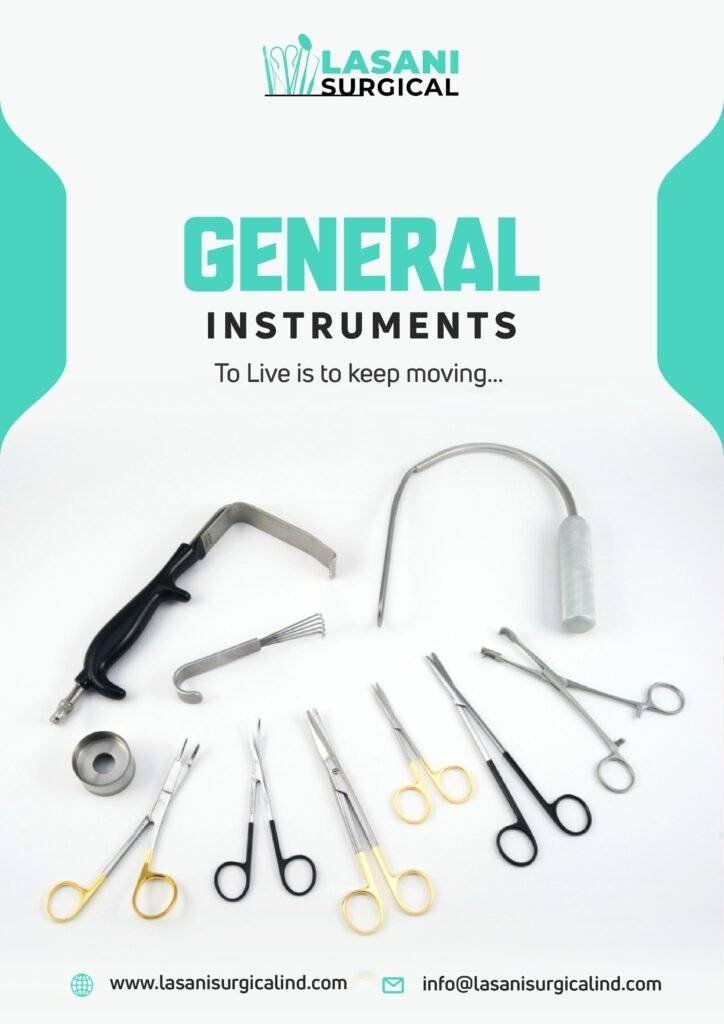

Surgical Instruments

Crafted with precision and care, our general surgical tools support safe and effective procedures in operating rooms worldwide.

Family & General Medicine

Diagnostic kits and basic surgical tools for general practitioners, built to deliver accuracy in everyday patient care.

Gynecology & Birthing Care

High-quality forceps, scissors, and clamps designed for gynecological and obstetric needs, ensuring safety for both mother and child.

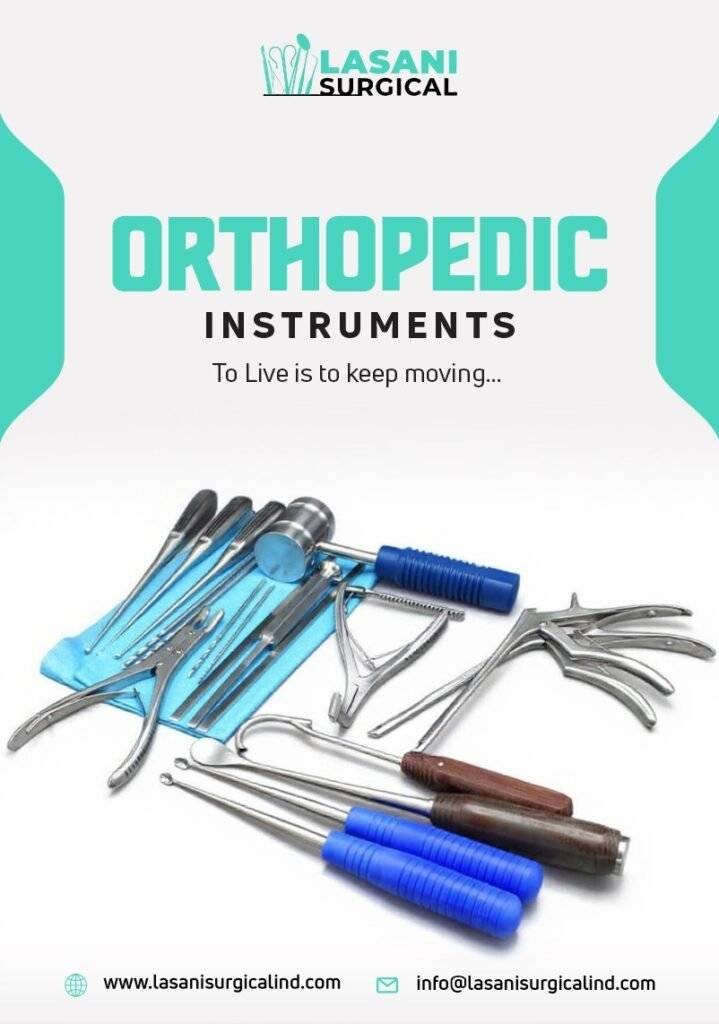

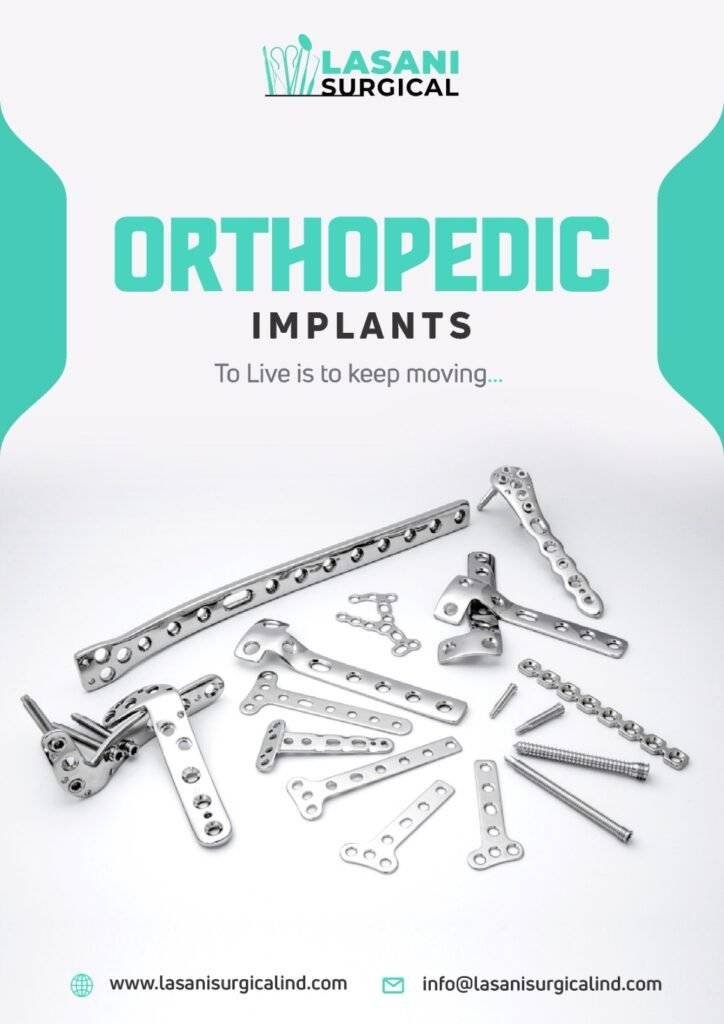

Orthopedic Instruments

Rigid, ergonomic tools for orthopedic procedures, including bone cutters, elevators, and chisels—engineered for strength and precision.

Bridging the Global Surgical Gap

At Lasani Surgical, a trusted Surgical Instruments Manufacturer, we recognize the critical need for accessible surgical care across the globe. With billions lacking essential services, our mission is to support healthcare professionals with high-quality, reliable surgical tools designed to meet international standards of safety, precision, and performance.

+

0

Billion

People around the world lack access to basic surgical care.

+

0

million

Lives are lost every year due to the lack of surgical services.

+

0

Million

Additional surgeries are required annually to meet global health needs.

0

Mission

To supply top-tier surgical instruments and solutions worldwide.

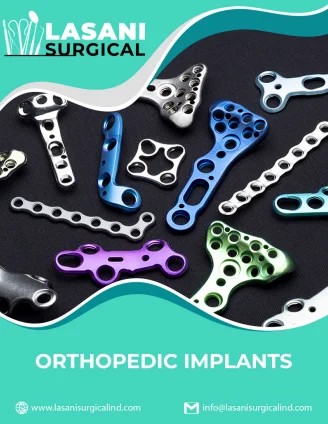

Our Catalogue

Featured Surgery Sets

Why Choose us ?

Our Production Tour

At Lasani Surgical Industry, a leading Surgical Instruments Manufacturer, our production journey begins with precision engineering and premium-grade stainless steel. Raw materials are carefully sourced and tested for compliance with international surgical standards before entering the machining phase. Using advanced CNC machines and conventional lathes, our skilled technicians shape and refine each surgical instrument with unmatched accuracy. Every instrument undergoes a strict dimensional inspection during the process to ensure consistency and reliability — from scalpels and forceps to complex orthopedic tools.

Once the basic form is achieved, each instrument goes through a rigorous series of grinding, polishing, heat treatment, and ultrasonic cleaning stages. Our finishing department ensures smooth, corrosion-resistant surfaces that meet surgical-grade sterility requirements. Final assembly is done under cleanroom conditions, followed by laser marking for traceability. Before packaging, every piece undergoes individual quality control checks — including sharpness tests, joint alignments, and surface integrity inspections. This transparent, hands-on production process is what makes Lasani a trusted Surgical Instruments Manufacturer, both locally and internationally.

customer testimonials

What Our Clients Says

Our Dedicated Team

Kabeer Hussain

CEO / Founder

Dr Noman Ali

Sales Manager

Dr. Moazam Ali

Production Manager

Sarah

Marketing Manager

More

More

- Home page

- Surgical Sets

Explore Our Surgery Sets

- Surgical Instruments

- Dental Instruments

- About Us

- Our Catalogue

- Blog

- Contact us